Small Chamber EB Welding Systems from Sciaky

Sciaky, through its partnership with EVOBEAM GmbH of Germany, now sells and supports advanced Rapid Cycle EB welding systems manufactured by EVOBEAM. These systems utilize low voltage and low power, and are ideally suited for rapid production of small-scale parts.

Customization of individual customer requirements is achieved by applying engineering principles focused on custom fit working envelopes, kinematic flexibility, mechanical precision, short pump down times, dry (hydrocarbon free) vacuum, proven EB gun and power supplies, and state-of-the-art CNC controls. Taking customer part production requirements into account, EVOBEAM Rapid Cycle EB welding systems can be configured for manual single part flow or adapted with automated high-volume part handling equipment.EVOBEAM 60 kV Gun (6-15 kW) - Rapid Single Piece Flow Machine

- Work envelope: D = 250mm, L =350 mm

- Working Vacuum ≤ 8 x 10-3 mbar in 6s

- Ultimate Vacuum ≤ 5 x 10-5 mbar

- Maintenance-free dry vacuum system (600 l/s)

- 60kN electro-mechanic pressing of work piece during process (force/displacement controlled)

- Electron optical seam tracking system (real time control system 3µs, 18bit)

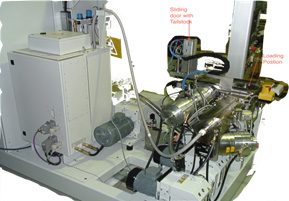

EVOBEAM 75 Top Loader EB Welding System

- Working Vacuum ≤ 1 x 10-4 mbar

- Maintenance-free vacuum system

- CNC X-Axis 75mm gun slide

- CNC A-Axis rotary

EVOBEAM cube 250 (400) EB Welding System

External Gun, X-Axis Gun Slide, Y-Axis Table

- Table size: per request

- Free height above table: Z = 360mm

- CNC Travel

- External Gun

- 250mm or 400mm

- Table in chamber: per request

- Chamber volume: per request

- Chamber type: stainless steel welded

- Rotary and Tailstock: CNC, per request

Available features and modules:

- 6-15 kW beam power (0,2mm spot @ 6kW, 250mm WD)

- 500 Hz Beam Pulsing

- High performance dry vacuum systems (up to 50.000 l/s)

- Siemens 840D CNC control, max. 31 axes

- Standard: 4 mechanical axes + 4 beam axes (IB, IL, IX, IY)

- Real-time control system (18 bit, 3µs) for

- Electron optical visualization

- Joint tracking

- Process control and free programmable deflection

- High speed deflection (±7°, 25kHz)

- Dynamic lens (1.000 Hz, 10% lift)

- Light optics with CCD camera,

- LED down beam illumination, cross hair and motorized vapor shield

- CNC Rotary tilt positioner