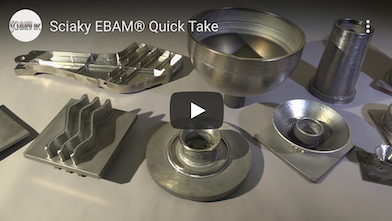

Sciaky's EBAM® technology is the only large-scale metal additive manufacturing process with approved parts in 4 dimensions:

Since 1939, Sciaky has provided innovative solutions for the manufacture of warplanes, warships, tanks, space shuttles, rockets, satellites, submarines and automobiles. No other industrial metal 3D printing provider has more approved applications on Land, Sea, Air, and Space than Sciaky’s Electron Beam Additive Manufacturing (EBAM®) technology.

That’s why the most advanced manufacturing companies in the world, including our nation’s defense and energy programs, come to Sciaky, time after time. It’s all about TRUST.

Contact us today and let our AM experts assist you with your next project.

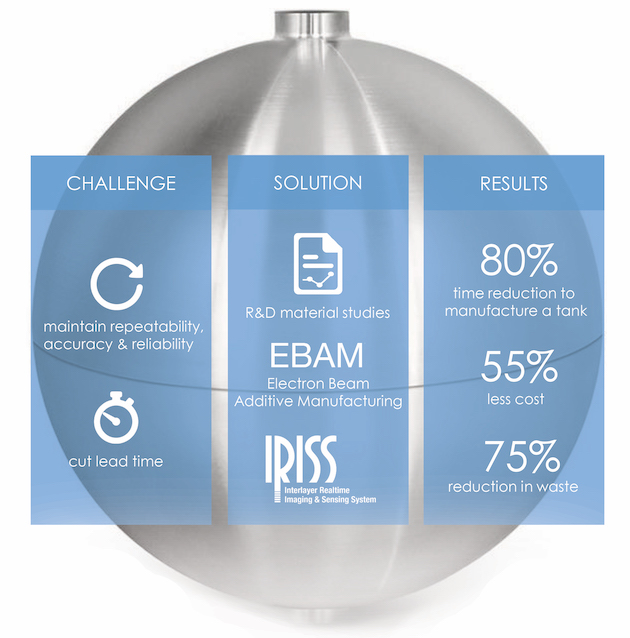

"If you're going to build a titanium tank for a satellite that we currently build, you have to buy a billet of forged titanium, and the latent time is 14 to 18 months to get it from the supplier, and then you have to machine it down to its final geometry. This machine, the Sciaky, lays it up bead by bead, and then you machine it to the final thickness, and you have two spheres and probably a barrel section for the final tank geometry. So you get a tank for a small satellite, machined in three pieces, and within a week's time." - Dennis Little, VP of Production at Lockheed Martin Space Systems

Read more at Aviation Week