Internal Moving & External EB Welding Guns

Overview of EB Welding Gun Design Options

Sciaky’s EB Welding Systems are powered by the most advanced electron beam welding guns in the market. We specialize in both EB internal moving gun and EB external gun designs.

Click on the tabs above for information on Sciaky’s industry-leading internal moving EB welding gun and its external EB welding gun.

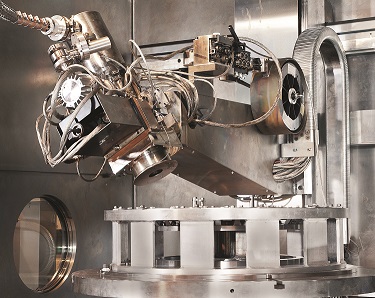

The Most Versatile Internal Moving EB Welding Gun on the Market

Sciaky’s exclusive 60/60 electron beam gun package has a narrow beam geometry, capable of producing welds with characteristics comparable to those produced by high voltage equipment. It also has superior operational stability. The direct-mounted, turbomolecular gun vacuum pump is equipped with isolation valves for superior performance and the easy access to gun components during filament change makes this gun package the most advanced in its class.

The gun can be mounted in various mechanical configurations with capability of servo axes of motion. Options include servo gun tilt and servo rotary mechanisms.

Click Here to Download Sciaky's Internal/Moving Gun EBW System Product Sheet

Total Process Control

Sciaky’s W2020 Computer Control provides total control over process parameters with +/- 1% accuracy and facilitates up to 10 axes of motion control. Capabilities include process monitoring with data acquisition, networking and off-line programming. The open architecture allows for easy upgrading.

The easy-to-use operator interface includes system diagnostics and three levels of program access for security. The viewing system features high-resolution, precision gun column optics with a high resolution camera and monitor. Controls for focus, shutter, iris and adjustable crosshair are provided.

Intuitive Operator Interface

Sciaky’s operator interface is confi gured for all routine programming, file manipulation and operative process control functions. Additional virtual hardware allows the beam supply to be enabled and provides chamber vacuum control, video control and deflection monitoring. A separate portable pendant can be provided for parameter display, program control, critical parameters override and mechanical axes jogging.

Options for Pumping Systems, Power Supply & Axes Motion

- Turbomolecular pump on gun

- Roughing and diffusion pumps on chamber

- 15 - 42kW power supply

- X, Y and Z are standard on all systems

- Horizontal or Vertical Rotary Positioner

- Rotary/Tilt Positioner

- Wirefeed, Motorized Wire Nozzle and EBAM (retrofitable or upgradeable)

- Custom Vision Systems

- Head and Tail Stock

- Hand Wheels/Joystick

- Carriage Runout Platform(s)

- Remote Process Monitoring

- Special Beam Deflection Systems

- Beam diagnostics

The Most Advanced External EB Welding Gun on the Market

Sciaky's external electron beam welding gun is the most advanced external EB welding gun on the market today.

The triode-designed 60kV external gun is manually adjustable within +/- 3 inches in the X direction, significantly improving narrow beam geometry. The gun's cantilever configuration makes filament replacement quick and easy. A direct-mounted turbomolecular pump, with an isolation valve, maintains the gun's vacuum at better than 1 x 10-4 Torr for superior performance. A high resolution CCD camera and monitor offer controls for optical focus, zoom, shutter, iris and an adjustable cross-hair for beam targeting. The gun column is constructed of stainless steel and utilizes internal coils for beam focusing and deflection.

Click Here to Download Sciaky's External Gun EBW System Product Sheet

Total Process Control

Sciaky's W2020 Computer Control provides total control over process parameters with +/- 1% accuracy and facilitates up to 6 axes of motion control. Capabilities include process monitoring with data acquisition, networking and off-line programming.

Intuitive Operator Interface

Sciaky's operator interface is configured for all routine programming, file manipulation and operative process control functions. Additional virtual hardware allows the beam supply to be enabled and provides chamber vacuum control, video control and deflection monitoring. A separate portable pendant can be provided for parameter display, program control, critical parameters override and mechanical axes jogging.

Options for Pumping Systems, Power Supply & Axes Motion

- Turbomolecular pump on gun

- Roughing and diffusion pumps on chamber

- Standard 4kW – 15kW power supply available

- X ; Y Axes Table

- Horizontal or Vertical Rotary Positioner

- Rotary/Tilt Positioner

- Wirefeed, Motorized Wire Nozzle

- Custom Vision Systems

- Head and Tail Stock

- Hand Wheels/Joystick

- Carriage Runout Platform(s)

- Remote Process Monitoring

- Special Beam Deflection Systems

Standard Chamber Sizes for Sciaky 60 kV External Electron Beam Gun Welding Systems

12 x 12 x 12 (300 x 300 x 300 mm)

18 x 18 x 18 (450 x 450 x 450 mm)

24 x 24 x 24 (600 x 600 x 600 mm)

36 x 36 x 36 (900 x 900 x 900 mm)

60 x 46 x 56 (1500 x 1160 x 1400 mm)

60 x 60 x 60 (1500 x 1500 x 1500 mm)